Safety parts within the automotive industry, such as the treated transmission element of the steering mechanism, are subject to the most severe conditions and controls within the production process.

汽车工业中的安全部件,例如转向装置中经处理的传动元件,在生产过程中经受最剧烈的条件和严格的控制

To meet these conditions, the nondestructive ultrasonic inspection for the detection of flaws due to the die-forming has been envisaged among other methods.

为了满足这些条件,因模具成型在众多无损检测方法中超声波无损检测已经在考虑当中

Typical flaws include overfoldings and cracks which are only seldom visually recognizable on the surface.

像典型的折叠和裂纹缺陷在表面上目视检测很难检测到。

SOLUTION:方案

The recommended immersion test arrangement is outlined in the figure:

下图推荐的水浸法检测示意图

Because of the defined flaw area, scanning in a fixed probe position is sufficient for the flaw detection using the H5K probe's large sound beam which is additionally expanded by being reflected from the curved backwall.

对于限定区域的缺陷检测,H5K探具有较大的声束宽度,被曲面反射后有更进一步的声束扩散,所以用H5K探头在一个固定的位置足够对缺陷进行检测。

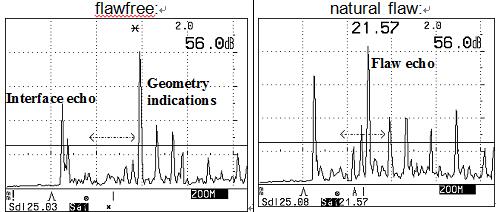

The component analysis is carried out by evaluating the flaw indications between the interface echo at sound entry and the indications from the geometry, such as edges – openings – holes.

通过对界面回波和几何回形状回波之间的回波信号评估来分析产品部件,例如工件边缘回波,开孔之类的回波是来自几何形状回波。

Typical CRT screen displays

CRT屏幕显示

SUITABLE EQUIPMENT:

适用的设备

Ultrasonic flaw detector:设备 USD 15X

USD 15X double-rack (for dual-trace testing due to component geometry)

Probe:探头 H 5 K